Square Column with Spiral Reinforcement

Spiral Spacing Calculation for Square Section – C20-S420

Example Problem

For a square column with C20-S420 materials shown in the figure, calculate the required spiral spacing using Ø8 spiral reinforcement. The column will carry the axial load that corresponds to its given longitudinal reinforcement.

Given: 8Ø16 longitudinal bars, Ø8 spiral

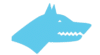

Square Column with Spiral Cross-Section

Given Information

| Parameter | Value |

|---|---|

| Column section | Square 500 × 500 mm |

| Spiral core diameter | D’ = 450 mm (inscribed circle) |

| Materials | C20-S420 (fcd = 13 MPa, fyd = 365 MPa, fck = 20 MPa, fywk = 365 MPa) |

| Longitudinal reinforcement | 8Ø16 (given) |

| Spiral bar diameter | Ø8 mm |

SOLUTION

Calculate Longitudinal Steel Area

Ast = 8 × 201 = 1,608 mm²

Calculate Column Areas

Ac = b × h = 500² = 250,000 mm²

Core area (circular spiral):

Ack = π D’²/4 = π × 450²/4 = 158,963 mm²

Calculate Column Axial Capacity

Nd = (0.85 × 13 × 250,000) + (365 × 1,608)

Nd = 2,762,500 + 586,920

Nd = 3,349,420 N ≈ 3,349.42 kN

This calculates the axial load capacity of the column based on the given 8Ø16 longitudinal reinforcement. This capacity will be used to determine if spiral reinforcement is required.

Check if Spiral is Required

3,349.42 × 10³ > 0.20 × 250,000 × 20

3,349,420 > 1,000,000 N

3,349.42 × 10³ > 1,000 × 10³ ✓

Calculate Required Volumetric Spiral Ratio

Two Conditions (Select Larger):

ρst ≥ 0.45 [(Ac/Ack) – 1] × (fck/fywk)

Condition 2:

ρst ≥ 0.12 × (fck/fywk)

Calculate Condition 1:

ρst ≥ 0.45 × [1.573 – 1] × 0.0548

ρst ≥ 0.45 × 0.573 × 0.0548

ρst ≥ 0.014

Calculate Condition 2:

ρst ≥ 0.12 × 0.0548

ρst ≥ 0.00657

Calculate Required Spiral Steel Area per Unit Height

Ast = 0.014 × 158,963

Ast = 2,225.5 mm²

This represents the required spiral cross-sectional area per millimeter of column height. This value will be used to determine the spiral pitch (vertical spacing).

Calculate Spiral Spacing from Requirements

Where:

D = core diameter = 450 mm

Aswt = area of spiral bar = π × 8²/4 = 50.24 mm²

Ast = 2,225.5 mm²

st = (3.14 × 450 × 50.24) / 2,225.5

st = 70,989.6 / 2,225.5

st = 31.89 mm → Round to 40 mm

Apply Code Maximum Spacing Limits

Maximum Spacing Requirements:

D/5 = 450/5 = 90 mm

80 mm

}

Therefore: st ≤ 80 mm

Our calculated spacing (40 mm) is well below the maximum allowed (80 mm), so it controls the design.

Design Summary

Final Column Design – Side View

| Parameter | Value | Status |

|---|---|---|

| Column section | 500 × 500 mm (square) | Given |

| Gross area (Ac) | 250,000 mm² | Calculated |

| Core diameter (D’) | 450 mm | Given |

| Core area (Ack) | 158,963 mm² | Circular area |

| Longitudinal steel | 8Ø16 = 1,608 mm² | Given |

| Column capacity (Nd) | 3,349.42 kN | Calculated |

| Spiral requirement check | 3,349.42 kN > 1,000 kN | ✓ Spiral required |

| Volumetric ratio (ρst) | 0.014 | Larger of two conditions |

| Required steel per unit height | 2,225.5 mm² | Calculated |

| Calculated spacing | 31.89 mm → 40 mm | Rounded up |

| Maximum allowed spacing | 80 mm | Code limit (min of D/5, 80mm) |

| Final spiral design | Ø8 / 40 mm | ✓ Controls design |

Key Design Insights

- Unique configuration: This is a square column section with circular spiral reinforcement – an uncommon but valid design approach combining benefits of both systems.

- Core area calculation: Even though the column is square (500×500), the spiral creates a circular confined core with diameter 450mm, giving Ack = 158,963 mm².

- High axial capacity: With Nd = 3,349 kN >> 0.20Acfck = 1,000 kN, the column is heavily loaded and clearly requires spiral reinforcement.

- Condition 1 governs: The volumetric ratio from Condition 1 (0.014) is larger than Condition 2 (0.00657), so it controls the design.

- Tight spiral spacing: The calculated 40mm spacing is quite tight, providing excellent confinement but requiring careful construction.

- Well below limits: Design spacing (40mm) is well below the maximum code limit (80mm), indicating conservative and safe design.

- Corners unconfined: Note that the square corners outside the circular spiral are not confined – this must be considered in seismic design.

Advantages and Considerations

Advantages:

- Excellent confinement within the circular core

- Continuous spiral (no weak zones)

- Good ductility and toughness

- Square section easier to form and connect to beams

Design Considerations:

- Corner regions outside spiral are unconfined

- May require additional corner reinforcement in seismic zones

- More complex construction than pure square or circular columns

- Tight spiral spacing (40mm) requires careful workmanship

Final Construction Specifications

COLUMN: 500 × 500 mm (Square Section)

Spiral Core Diameter: 450 mm

Longitudinal Reinforcement: 8Ø16

(8 bars of 16mm diameter)

Spiral Reinforcement: Ø8 @ 40 mm pitch

(Continuous circular spiral, 8mm diameter, 40mm vertical spacing)

Materials: C20 Concrete, S420 Steel

Axial Capacity: Nd = 3,349 kN

- Spiral continuity: Ensure spiral is continuous or properly lap-spliced (minimum 48db)

- Tight spacing: 40mm spacing is tight – use proper spacers to maintain uniform pitch

- Longitudinal bar placement: 8 bars should be positioned around the perimeter, with at least one bar in each corner plus mid-face positions

- Corner confinement: Consider additional measures for corner regions in seismic applications

- Spiral anchorage: Provide 1.5 extra spiral turns at top and bottom with proper anchorage

- Concrete placement: Tight spiral may make concrete placement challenging – use appropriate consolidation methods

- Quality control: Verify spiral spacing during construction – tolerance should not exceed ±5mm

- Professional review: All designs must be reviewed by a licensed structural engineer