Spiral Column Design

Longitudinal Reinforcement and Spiral Spacing – C20-S420

Example Problem

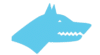

For a spiral column shown in the figure, made of C20-S420 materials, subjected to an axial load Nd = 2940 kN:

a) Calculate the required longitudinal reinforcement area using Ø20 diameter bars.

b) Calculate the spiral spacing using Ø8 spiral reinforcement.

Spiral Column Cross-Section

Given Information

| Parameter | Value |

|---|---|

| Column type | Circular spiral column (Fretli kolon) |

| Diameter | D = 350 mm |

| Core diameter | D’ = 400 mm (outer diameter), dck = 400 mm |

| Materials | C20-S420 (fcd = 13.3 MPa, fyd = 365 MPa) |

| Design axial force | Nd = 2940 kN |

| Longitudinal bar diameter | Ø20 mm |

| Spiral bar diameter | Ø8 mm |

PART A: LONGITUDINAL REINFORCEMENT CALCULATION

Calculate Column Areas

Ac = π d²/4 = π × 400²/4 = 125,600 mm²

Core area (inside spiral):

Ack = π D’²/4 = π × 350²/4 = 96,163 mm²

Calculate Required Steel Area Using Basic Equation

2940 × 10³ = 0.85 × 13 × 125,600 + 365 Ast

2940 × 10³ = 1,387,960 + 365 Ast

365 Ast = 2,940,000 – 1,387,960

365 Ast = 1,552,040

Ast = 4252.4 mm²

– 0.85 fcd Ac: Concrete contribution to axial capacity

– fyd Ast: Steel contribution to axial capacity

Determine Number of Longitudinal Bars

Area of one Ø20 bar = π × 20²/4 = 314 mm²

Required number of bars:

n = Ast / (area per bar)

n = 4252.4 / 314 = 13.5 → Round up to 14 bars

Provided area: 14 × 314 = 4,396 mm²

Required area: 4,252.4 mm²

4,396 > 4,252.4 ✓

PART B: SPIRAL SPACING CALCULATION

Check Section Adequacy for Spiral Columns

2940 × 10³ > 0.20 × 125,600 × 20

2940 × 10³ > 502,400 N

2,940,000 > 502,400 ✓

Calculate Required Volumetric Spiral Ratio (ρst)

Spiral Ratio Formula (Two conditions – select larger):

ρst ≥ 0.45 [(Ac/Ack) – 1] × (fck/fywk)

Condition 2:

ρst ≥ 0.12 × (fck/fywk)

Calculate Condition 1:

ρst ≥ 0.45 × [1.306 – 1] × 0.0548

ρst ≥ 0.45 × 0.306 × 0.0548

ρst ≥ 0.0075

Calculate Condition 2:

ρst ≥ 0.12 × 0.0548

ρst ≥ 0.00657

Calculate Required Spiral Area per Unit Height

Ast = 0.0075 × 96,163 = 721.22 mm²

This is the required spiral steel area per unit height of column. It represents how much spiral reinforcement cross-sectional area is needed per mm of column height.

Calculate Spiral Spacing

Where:

D = core diameter = 350 mm

Aswt = area of spiral bar = π × Ø²/4 = π × 8²/4 = 50.24 mm²

Ast = required area per unit height = 721.22 mm²

st = (3.14 × 350 × 50.24) / 721.22

st = 55,234.48 / 721.22

st = 76.55 mm → Round to 77 mm

Apply Code Limits for Spiral Spacing

Maximum Spacing Limits:

D/5 = 350/5 = 70 mm

80 mm

}

Therefore: st ≤ 70 mm

Decision: Must use maximum allowed spacing: st = 70 mm

Design Summary

Final Spiral Column Design

| LONGITUDINAL REINFORCEMENT | ||

|---|---|---|

| Parameter | Value | Status |

| Column diameter | D = 350 mm | Given |

| Gross area (Ac) | 125,600 mm² | Calculated |

| Core area (Ack) | 96,163 mm² | Calculated |

| Required steel area | 4,252.4 mm² | From equilibrium |

| Final longitudinal design | 14Ø20 | 4,396 mm² ✓ |

| SPIRAL REINFORCEMENT | ||

|---|---|---|

| Parameter | Value | Status |

| Adequacy check | 2,940 kN > 502.4 kN | ✓ Spiral required |

| Volumetric ratio – Condition 1 | ρst ≥ 0.0075 | Calculated |

| Volumetric ratio – Condition 2 | ρst ≥ 0.00657 | Calculated |

| Selected volumetric ratio | ρst = 0.0075 | Larger value selected |

| Required area per unit height | Ast = 721.22 mm² | Calculated |

| Calculated spacing | 76.55 mm → 77 mm | From formula |

| Maximum allowed spacing | 70 mm (D/5) | Code limit |

| Final spiral design | Ø8 / 70 mm | ✓ Code compliant |

Key Design Insights

- Spiral vs. Tied columns: Spiral columns provide better confinement and ductility compared to tied columns due to continuous spiral reinforcement.

- High axial load: Nd = 2,940 kN greatly exceeds 0.20Acfck = 502.4 kN, confirming the need for spiral reinforcement.

- Two spiral ratio conditions: Code requires checking both formulas and using the larger value (0.0075 vs. 0.00657).

- Code limits govern: Calculated spacing (77 mm) exceeds maximum allowed (70 mm), so code limit controls the design.

- Core diameter: The confined core diameter (D’ = 350 mm) is measured to the centerline of the spiral.

- Longitudinal bars: 14Ø20 bars are distributed evenly around the column perimeter for balanced reinforcement.

- Construction: Spiral must be continuous (no splices) or spliced with proper lap length per code requirements.

Advantages of Spiral Columns

- Superior confinement: Continuous spiral provides better concrete confinement than discrete ties

- Enhanced ductility: Confined concrete exhibits more ductile behavior under compression

- Higher strength: Confinement increases effective concrete strength

- Better performance: Particularly beneficial in seismic regions

- Uniform reinforcement: No weak zones as with tied columns

Final Construction Specifications

SPIRAL COLUMN: Ø400 mm (Outer diameter)

Core Diameter: 350 mm (to centerline of spiral)

Longitudinal Reinforcement: 14Ø20

(14 bars of 20mm diameter, equally spaced around perimeter)

Spiral Reinforcement: Ø8 @ 70 mm pitch

(Continuous spiral, 8mm diameter, 70mm vertical spacing)

Materials: C20 Concrete, S420 Steel

Cover: 25-30 mm to spiral

- Spiral reinforcement must be continuous or properly lap-spliced (minimum 48db lap length)

- Maintain accurate spiral spacing throughout column height – use spacers if needed

- Longitudinal bars must be positioned accurately around the perimeter (angular spacing = 360°/14 ≈ 25.7°)

- Ensure adequate concrete cover to spiral (25-30mm minimum)

- Spiral must be anchored properly at top and bottom with 1.5 extra turns

- All designs must be reviewed by a licensed structural engineer

- Follow local building codes for specific requirements in your region