RC Column Design: Longitudinal & Shear Reinforcement

Step-by-Step Solution with Tie Spacing Calculation

Problem Statement

Design a reinforced concrete rectangular column for a multi-story commercial building. The column must resist both axial load and minimum moment conditions. Calculate:

1. Longitudinal steel reinforcement (main bars)

2. Transverse reinforcement (ties/stirrups) for shear

Material Properties

| Property | Value | Description |

|---|---|---|

| Concrete Class | C25 | fck = 25 MPa |

| Steel Class | S420 | fyk = 420 MPa |

| fcd | 16.67 MPa | Design concrete strength (25/1.5) |

| fyd | 365 MPa | Design steel strength (420/1.15) |

| Cover | d’ = 25 mm | Concrete cover to main reinforcement |

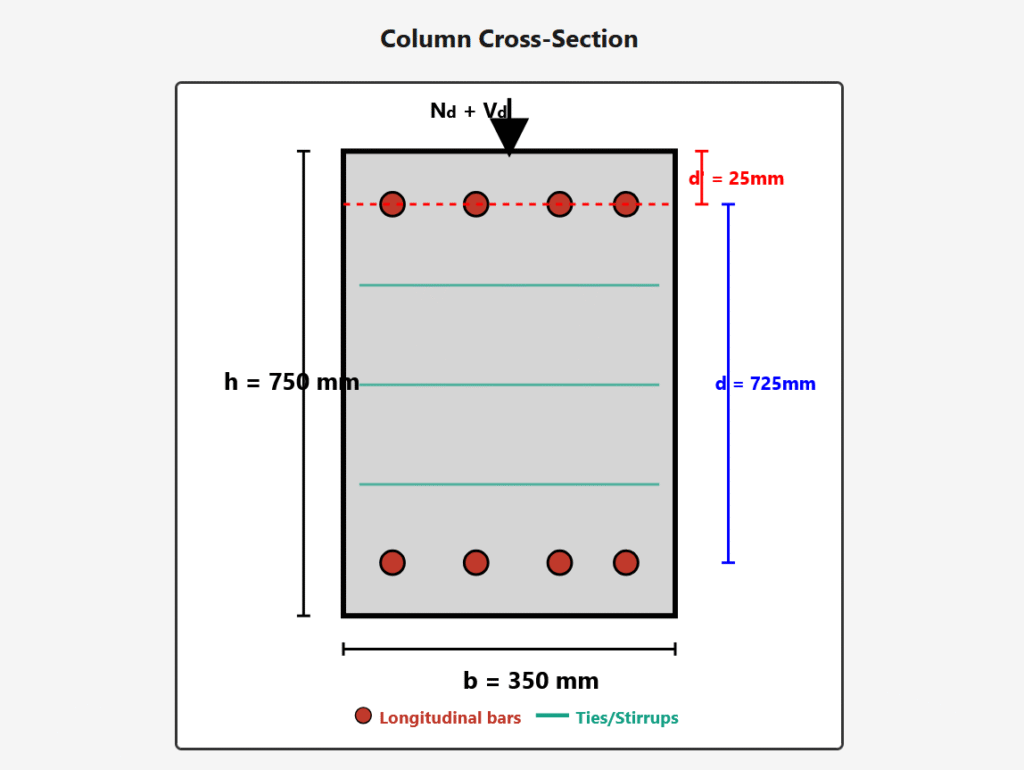

Column Geometry and Loading

Column Cross-Section

- Width (b): 350 mm

- Height (h): 750 mm

- Cover (d’): 25 mm

- Effective depth (d): 750 – 25 = 725 mm

- Reinforcement: 8 longitudinal bars + transverse ties

Design Loading

| Load Type | Value |

|---|---|

| Axial Force (Nd) | 1150 kN |

| Minimum Moment Condition | emin = 15 + 0.03h |

| Shear Force (Vd) | 185 kN |

PART 1: LONGITUDINAL REINFORCEMENT DESIGN

Calculate Minimum Eccentricity

emin = 15 + 0.03 × 750

emin = 15 + 22.5 = 37.5 mm ≈ 38 mm

Even if the column is designed for purely axial load, codes require a minimum eccentricity to account for construction imperfections, material variations, and unforeseen moments. This ensures more realistic and safer design.

Calculate Design Moment

Md = 1150 × 38

Md = 43,700 kN·mm = 43.7 kNm

This is the minimum bending moment that must be considered in the design, calculated from the axial load and minimum eccentricity. The column must resist both this moment and the axial force simultaneously.

Calculate Normalized Parameters

ν = Nd / (b × h × fcd)

ν = 1,150,000 / (350 × 750 × 16.67)

ν = 1,150,000 / 4,375,875

ν = 0.263 ≈ 0.26

μ = Md / (b × h² × fcd)

μ = 43.7 × 10⁶ / (350 × 750² × 16.67)

μ = 43.7 × 10⁶ / 3,281,906,250

μ = 0.0133 ≈ 0.013

Determine Steel Coefficient from Charts

From interaction diagram: ψ ≈ 0.08

Note: Since the moment is very small (minimum moment condition),

we will likely need minimum steel reinforcement.

Calculate Required Steel Ratio

ρs = 0.08 × (16.67 / 365)

ρs = 0.08 × 0.0457

ρs = 0.00365 = 0.365%

ρmin = 1.0%

ρmax = 4.0%

ρs,calculated = 0.365% < ρmin = 1.0%

→ Use ρmin = 1.0%

Calculate Total Steel Area Required

Ast = 0.01 × 350 × 750

Ast = 2,625 mm²

Select Bar Size and Number

Area per bar = Ast / n = 2,625 / 8 = 328 mm²

Required diameter:

Ø = √(4A/π) = √(4 × 328 / π) = √(417.8) = 20.4 mm

Select: Ø22 mm (next standard size up)

Verification:

Area of Ø22 = π × 22²/4 = 380 mm²

Total provided = 8 × 380 = 3,040 mm²

3,040 mm² > 2,625 mm² ✓

Provided steel ratio: 3,040/(350×750) = 1.16% > 1.0% ✓

PART 2: SHEAR REINFORCEMENT DESIGN (TIES)

Check if Shear Reinforcement is Required

VRd = 0.22 × Asw × fcd

Where Asw is the area of shear reinforcement per unit length

For minimum shear capacity check:

Vd = 185 kN

Since we have shear force, we need to design ties.

Calculate Required Tie Area

d = h – d’ = 750 – 25 = 725 mm

Check concrete alone capacity:

Vcr = 0.65 × fctd × b × d × (1 + 0.07 × Nd/Ac)

Where fctd = 1.15 MPa (for C25)

Vcr = 0.65 × 1.15 × 350 × 725 × (1 + 0.07 × 1150×10³/(350×750))

Vcr = 0.65 × 1.15 × 350 × 725 × (1 + 0.07 × 4.38)

Vcr = 190,344 × 1.307

Vcr = 248,720 N = 248.7 kN

Since Vd = 185 kN < Vcr = 248.7 kN

→ Minimum shear reinforcement required

Design Minimum Ties

Asw = 2 × (π × 10²/4) = 2 × 78.5 = 157 mm²

For minimum reinforcement:

(Asw/s) ≥ 0.3 × (fctd/fywd) × b

Where fywd = 365 MPa, fctd = 1.15 MPa

(157/s) ≥ 0.3 × (1.15/365) × 350

(157/s) ≥ 0.330

s ≤ 157/0.330 = 475 mm

s ≤ b/2 = 350/2 = 175 mm

s ≤ 12Ømin = 12 × 22 = 264 mm (min. longitudinal bar)

s ≤ 200 mm (general limit for columns)

Governing: s ≤ 175 mm

Select: s = 150 mm (standard spacing)

(Two-leg stirrups at 150 mm spacing)

Final Design Summary

| Design Element | Requirement | Provided | Status |

|---|---|---|---|

| Column dimensions | 350 × 750 mm | 350 × 750 mm | ✓ |

| Axial load capacity | Nd = 1,150 kN | Adequate | ✓ |

| Moment capacity | Md = 43.7 kNm | Adequate | ✓ |

| Steel area required | 2,625 mm² | 3,040 mm² | ✓ |

| Steel ratio | ρmin = 1.0% | 1.16% | ✓ |

| Longitudinal bars | 8Ø22 | 8Ø22 | ✓ |

| Shear capacity | Vd = 185 kN | Vcr = 248.7 kN | ✓ |

| Ties/Stirrups | Min. required | Ø10 @ 150 mm | ✓ |

Design Verification Checklist

Longitudinal Reinforcement:

- Number of bars: 8 bars (adequate for rectangular column) ✓

- Bar diameter: Ø22 mm (standard size) ✓

- Steel ratio: 1.16% (between 1% and 4% limits) ✓

- Clear spacing: (350 – 2×25 – 4×22)/(3) = 71 mm > 25 mm ✓

- Bar distribution: 4 bars on each long face ✓

Transverse Reinforcement:

- Tie diameter: Ø10 mm (≥ Ø8 mm minimum) ✓

- Tie spacing: 150 mm (≤ 175 mm maximum) ✓

- Configuration: Closed rectangular ties ✓

- Number of legs: 2 (adequate for this width) ✓

Detailing Requirements:

- Concrete cover: 25 mm (adequate for indoor exposure) ✓

- Tie hooks: 135° hooks with 10Ø extensions ✓

- Corner bars: All corner positions have longitudinal bars ✓

Key Design Points

- Minimum moment condition: The column is designed for minimum eccentricity (38 mm) resulting in small moment (43.7 kNm)

- Axial load dominance: Normalized axial force ν = 0.26 indicates moderate compression

- Minimum steel controls: Calculated steel (0.365%) is less than code minimum (1.0%)

- Shear capacity: Concrete alone provides 248.7 kN > 185 kN required, but minimum ties still needed

- Tie spacing: Governed by b/2 = 175 mm; using 150 mm for better confinement

- Practical design: 8 bars provide symmetric arrangement and ease of construction

Construction Drawing Specification

COLUMN DIMENSIONS: 350 × 750 mm

LONGITUDINAL REINFORCEMENT: 8Ø22

TRANSVERSE REINFORCEMENT: Ø10 @ 150 mm c/c

CONCRETE GRADE: C25 (fck = 25 MPa)

STEEL GRADE: S420 (fyk = 420 MPa)

CONCRETE COVER: 25 mm

TIE HOOKS: 135° with 10Ø extension