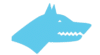

Square RC Column with Double Ties

Biaxial Bending & Shear Reinforcement Design

Problem Statement

Design a square reinforced concrete column subjected to combined axial load, biaxial bending moment, and shear force. Determine:

a) Column adequacy and required longitudinal reinforcement

b) Double tie configuration and spacing for Ø8 mm stirrups

Material Properties

| Property | Value | Description |

|---|---|---|

| Concrete Class | C20 | fck = 20 MPa |

| Steel Class | S420 | fyk = 420 MPa |

| fcd | 13.33 MPa | Design concrete strength (20/1.5) |

| fyd | 365 MPa | Design steel strength (420/1.15) |

| fctd | 1.0 MPa | Design tensile strength |

| Cover | d’ = 30 mm | Concrete cover to reinforcement |

Column Geometry and Loading

Square Column Cross-Section with Double Ties

- Width (b): 300 mm

- Height (h): 300 mm (square section)

- Cover (d’): 30 mm

- Effective depth (d): 300 – 30 = 270 mm

- Reinforcement: 8 corner & intermediate bars + double ties

- Loading: Biaxial bending with shear

Design Loading Conditions

| Load Type | Value |

|---|---|

| Axial Force (Nd) | 235 kN |

| Bending Moment (Md) | 96.53 kNm |

| Shear Force (Vd) | 240 kN |

Note: These are factored ultimate limit state loads including biaxial effects.

PART A: LONGITUDINAL REINFORCEMENT DESIGN

Check Column Dimensions Adequacy

Where:

Ac = b × h = 300 × 300 = 90,000 mm²

fck = 20 MPa

Ndm = 0.5 × 90,000 × 20 = 900,000 N = 900 kN

Nd = 235 kN ≤ 900 kN ✓

Calculate Effective Depth Ratio

d”/h = 0.9

Or as given in notation: d”/h = 240/300 = 0.8 (to center of reinforcement)

Calculate Normalized Axial Force

ν = 235,000 / (300 × 300 × 13.33)

ν = 235,000 / 1,199,700

ν = 0.196 ≈ 0.20

Calculate Normalized Bending Moment

μ = 96.53 × 10⁶ / (300 × 300² × 13.33)

μ = 96,530,000 / 359,910,000

μ = 0.268 ≈ 0.27

Determine Steel Coefficient from Interaction Diagram

With ν = 0.20 and μ = 0.27

Read: ψ ≈ 0.60

Calculate Required Steel Ratio

ρs = 0.60 × (13.33 / 365)

ρs = 0.60 × 0.0365

ρs = 0.0219 ≈ 0.021 = 2.1%

ρmin = 1.0%, ρmax = 4.0%

ρs = 2.1% is within limits ✓

Calculate Total Required Steel Area

Ast = 0.021 × 300 × 300

Ast = 1,890 mm²

Select Bar Size and Number

Required area per bar = Ast / n = 1,890 / 8 = 236.25 mm²

For circular bar: A = πز/4

Ø = √(4A/π) = √(4 × 236.25 / π) = √(300.2) = 17.33 mm

Round up to standard size: Ø18 mm

Verification:

Area of Ø18 = π × 18²/4 = 254 mm²

Total provided = 8 × 254 = 2,032 mm²

2,032 mm² > 1,890 mm² ✓

Longitudinal Reinforcement: 8Ø18

Steel ratio provided: 2,032/(300×300) = 2.26% ✓

PART B: SHEAR REINFORCEMENT DESIGN (DOUBLE TIES)

Calculate Concrete Shear Capacity

Vd ≤ 0.22 × Asw × fcd

For preliminary check:

240,000 N ≤ (0.22 × 300 × 13.33) = 879.8 N/mm × h

This is a minimum check; detailed capacity calculation needed.

Calculate Effective Depth for Shear

Calculate Concrete Shear Resistance

Where fctd = 1.0 MPa (for C20)

Vcr = 0.65 × 1.0 × 300 × 270 × (1 + 0.07 × 235,000/90,000)

Vcr = 52,650 × (1 + 0.07 × 2.611)

Vcr = 52,650 × (1 + 0.183)

Vcr = 52,650 × 1.183

Vcr = 62,285 N ≈ 62.3 kN

Vd = 240 kN > Vcr = 62.3 kN

→ Shear reinforcement is required!

Calculate Required Stirrup Area

Using Ø8 ties: Asw1 = π × 8²/4 = 50.24 mm²

Total stirrup area for 4 legs:

Asw = 4 × 50.24 = 200.96 mm²

Calculate Shear Carried by Concrete

Vc = 0.8 × 62.3 = 49.8 kN

Shear to be carried by stirrups:

Vs = Vd – Vc

Vs = 240 – 49.8 = 190.2 kN

Calculate Required Stirrup Spacing

s = (Asw × fyd × d) / Vs

s = (200.96 × 365 × 270) / 190,200

s = 19,794,552 / 190,200

s = 104.1 mm

Check Maximum Spacing Limits

s ≤ b/3 = 300/3 = 100 mm

s ≤ 12Ømin = 12 × 18 = 216 mm

s ≤ 150 mm (general limit)

Calculated: s = 104 mm

Governing: s ≤ 100 mm (b/3 criterion)

Verify Minimum Shear Reinforcement

(Asw/s) ≥ 0.3 × (fctd/fywd) × b

(200.96/100) ≥ 0.3 × (1.0/365) × 300

2.0096 ≥ 0.3 × 0.00274 × 300

2.0096 ≥ 0.247 ✓

Select Final Tie Spacing

(Meets both strength and maximum spacing requirements)

Double Tie Configuration: Ø8 @ 100 mm c/c

(Two overlapping rectangular ties at 100mm spacing)

Complete Design Summary

| Design Parameter | Required | Provided | Status |

|---|---|---|---|

| Column dimensions | 300 × 300 mm | 300 × 300 mm | ✓ |

| Axial load | Nd = 235 kN | Capacity adequate | ✓ |

| Bending moment | Md = 96.53 kNm | Capacity adequate | ✓ |

| Shear force | Vd = 240 kN | Stirrups provided | ✓ |

| Normalized values | ν = 0.20, μ = 0.27 | From analysis | ✓ |

| Steel coefficient | ψ = 0.60 | From diagram | ✓ |

| Steel ratio | ρs = 2.1% | 2.26% | ✓ |

| Steel area | 1,890 mm² | 2,032 mm² | ✓ |

| Longitudinal steel | 8 bars | 8Ø18 | ✓ |

| Concrete shear | Vcr = 62.3 kN | Vc = 49.8 kN | ✓ |

| Steel shear | Vs = 190.2 kN | Provided by ties | ✓ |

| Stirrup spacing | s ≤ 100 mm | 100 mm | ✓ |

| Transverse steel | Double ties | Ø8 @ 100 mm | ✓ |

Double Tie Configuration Details

What are Double Ties?

- Two overlapping rectangular stirrups in the same section

- Each tie encloses different corner bars

- Provides 4 vertical legs on each face (2 from each tie)

- Superior confinement compared to single ties

- Better control of longitudinal bar buckling

Advantages for Biaxial Loading:

- Enhanced confinement in both directions

- Better distribution of shear resistance

- Improved ductility under biaxial bending

- All longitudinal bars are laterally supported

Design Verification:

- Tie diameter: Ø8 mm (adequate for Ø18 longitudinal bars) ✓

- Spacing: 100 mm (≤ b/3, ≤ 12Ø, ≤ 150mm) ✓

- Number of legs: 4 per section (excellent shear capacity) ✓

- Shear capacity: Vd = 240 kN < Vu (ultimate) ✓

Key Design Insights

- Biaxial loading: The diagonal orientation in the cross-section indicates biaxial bending effects considered in design

- Moment-dominated: High μ = 0.27 with moderate ν = 0.20 indicates bending controls design

- High reinforcement: Steel ratio of 2.26% is above minimum, driven by bending moment requirements

- Shear critical: Vd = 240 kN is much higher than concrete capacity (62.3 kN), requiring substantial stirrups

- Double tie advantage: 4 legs per section provide 200.96 mm² shear area, doubling single tie capacity

- Close spacing: 100mm spacing governed by b/3 requirement ensures excellent confinement

- Ductile design: Double ties enhance ductility, critical for columns under biaxial loading

- Practical construction: 8 bars with double ties provides symmetric arrangement for biaxial behavior

Construction Drawing Specification

SQUARE COLUMN: 300 × 300 mm

LONGITUDINAL REINFORCEMENT: 8Ø18

TRANSVERSE REINFORCEMENT: DOUBLE TIES Ø8 @ 100 mm c/c

TIE CONFIGURATION: Two overlapping rectangular stirrups

CONCRETE GRADE: C20 (fck = 20 MPa)

STEEL GRADE: S420 (fyk = 420 MPa)

CONCRETE COVER: 30 mm clear

TIE HOOKS: 135° with 10Ø extension, alternated at corners

DESIGN LOADS: Nd=235kN, Md=96.53kNm, Vd=240kN