Reinforced Concrete Column Design

Original Problem – Complete Solution

Problem Statement

Design a reinforced concrete column for a 5-story commercial building. The column is located on the ground floor and must support loads from the upper floors. Calculate the required steel reinforcement.

Given Materials and Properties

| Property | Value | Description |

|---|---|---|

| Concrete Class | C25 | Characteristic compressive strength: 25 MPa |

| Steel Class | S420 | Yield strength: 420 MPa |

| fcd | 16.67 MPa | Design concrete strength = 25/1.5 |

| fyd | 365 MPa | Design steel strength = 420/1.15 |

| fck | 25 MPa | Characteristic concrete strength |

Column Dimensions and Loading

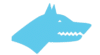

Column Cross-Section

- Width (b): 400 mm

- Height (h): 600 mm

- Cover: 40 mm on all sides

- Effective depth (d*): 600 – 40 = 560 mm

- Configuration: 8 steel reinforcement bars (shown as red circles)

Loading Conditions

The column must be designed for the following load combination:

| Load Type | Axial Force (Nd) | Bending Moment (Md) |

|---|---|---|

| Design Load | 1200 kN | 180 kNm |

Note: This represents the factored loads including dead load, live load, and partial safety factors.

SOLUTION – Step by Step Design Process

Verify Column Dimensions are Adequate

Where:

Ac = b × h = 400 × 600 = 240,000 mm²

fck = 25 MPa

Ndm = 0.5 × 240,000 × 25 = 3,000,000 N = 3,000 kN

Nd = 1,200 kN ≤ 3,000 kN ✓

We verified that the concrete cross-section is large enough to handle the axial load. The factor 0.5 accounts for the fact that we don’t use 100% of the concrete’s capacity for safety reasons. Since 1,200 < 3,000, we can proceed with these dimensions.

Calculate Effective Depth Ratio

This tells us where the reinforcement is positioned within the column. A ratio of 0.93 means the steel bars are positioned 93% of the way down from the top (accounting for concrete cover). This value is used to reference design charts for determining required steel amounts.

Calculate Normalized Axial Force

ν = 1,200,000 / (400 × 600 × 16.67)

ν = 1,200,000 / 4,000,800

ν = 0.30

The normalized axial force (ν = 0.30) means we’re using 30% of the column’s concrete compression capacity. This dimensionless number allows us to use standardized design charts regardless of column size.

Calculate Eccentricity

e = 180 × 10⁶ / 1,200 × 10³

e = 150 mm

emin = 15 + 0.003h = 15 + 0.003(600) = 15 + 1.8 = 16.8 mm

Our e = 150 mm > 16.8 mm ✓

Eccentricity (e = 150 mm) is the distance from the column centerline where the load effectively acts. A larger eccentricity means more bending effect. Our eccentricity is well above the minimum required value, indicating significant bending that must be accounted for in the design.

Calculate Normalized Bending Moment

μ = 180 × 10⁶ / (400 × 600² × 16.67)

μ = 180 × 10⁶ / 2,400,480,000

μ = 0.075

The normalized moment (μ = 0.075) represents what fraction of the column’s moment capacity is being used. This is a relatively low value, suggesting the column is not heavily stressed in bending.

Determine Steel Coefficient (ψ) from Design Chart

– ν = 0.30 (normalized axial force)

– μ = 0.075 (normalized moment)

– d*/h = 0.93

Result: ψ ≈ 0.08

The steel coefficient (ψ = 0.08) comes from interaction diagrams that account for the combined effect of axial force and bending moment. This coefficient will help us calculate how much steel reinforcement is needed.

Calculate Required Steel Ratio

ρs = 0.08 × (16.67 / 365)

ρs = 0.08 × 0.0457

ρs = 0.00365 = 0.365%

ρmin = 1.0% (code requirement)

ρs,calculated = 0.365% < ρmin

Decision: We must use ρmin = 1.0%

Even though our calculations show 0.365% is structurally sufficient, building codes require at least 1% steel reinforcement in columns to ensure:

- Adequate ductility (ability to deform without sudden failure)

- Control of shrinkage and temperature cracks

- Reserve strength for unexpected loads

- Better long-term structural behavior

Calculate Total Required Steel Area

Ast = 0.01 × 400 × 600

Ast = 2,400 mm²

We need a total of 2,400 mm² of steel reinforcement distributed around the column perimeter. This is the combined cross-sectional area of all reinforcement bars. Now we need to select the number of bars and their individual diameters.

Select Number and Size of Reinforcement Bars

Required area per bar = Ast / n = 2,400 / 8 = 300 mm²

For circular bar: A = πز/4

Solving for Ø:

Ø = √(4A/π) = √(4 × 300 / π) = √(381.97) = 19.54 mm

Available diameters: …, 16, 18, 20, 22, 25, 28, …mm

Since we need 19.54 mm, we round UP to the next standard size: Ø20 mm

Important: Always round up to ensure adequate steel area!

Verify Final Design

Area of Ø20 bar = π × 20²/4 = 314 mm²

Total area provided = 8 × 314 = 2,512 mm²

Required area = 2,400 mm²

Check: 2,512 > 2,400 ✓

(Eight bars of 20mm diameter)

- Provided steel area: 2,512 mm²

- Required steel area: 2,400 mm²

- Excess: 112 mm² (4.7% over – acceptable)

- Steel ratio provided: 2,512/(400×600) = 1.05% > 1.0% minimum ✓

Design Summary

| Parameter | Value | Status |

|---|---|---|

| Column dimensions | 400 mm × 600 mm | Adequate ✓ |

| Design axial force | 1,200 kN | Within capacity ✓ |

| Design bending moment | 180 kNm | Within capacity ✓ |

| Required steel area | 2,400 mm² | Provided: 2,512 mm² ✓ |

| Steel ratio | ρmin = 1.0% | Provided: 1.05% ✓ |

| Final reinforcement | 8Ø20 | Acceptable ✓ |

Additional Design Considerations

Bar Spacing:

- Minimum clear spacing between bars: 25 mm (greater of bar diameter or 25mm)

- With 8 bars of Ø20 in a 400×600 column: adequate spacing is achieved ✓

Transverse Reinforcement (Ties/Stirrups):

- Minimum tie diameter: Ø8 mm (at least 1/4 of longitudinal bar diameter)

- Maximum spacing: 300 mm or 15 times longitudinal bar diameter

- Recommended: Ø10 @ 250 mm spacing

Concrete Cover:

- Specified cover: 40 mm (measured to ties, not longitudinal bars)

- Ensures durability and fire resistance

Key Design Insights

- Column is lightly loaded: Using only 40% of concrete capacity (1,200 kN vs 3,000 kN max)

- Minimum steel governs: Required 0.365% but using 1.05% due to code minimum

- Moderate eccentricity: 150 mm (25% of column width) indicates some bending but not excessive

- Efficient design: 8 bars provide good distribution and constructability

- Safety margins: All checks passed with room to spare

Construction Drawing Specification

COLUMN: 400 × 600 mm

Longitudinal Steel: 8Ø20

Ties: Ø10 @ 250 mm

Concrete: C25

Steel: S420

Cover: 40 mm