Column Shear Reinforcement Design (Transverse Reinforcement)

Design of Stirrups/Ties for Rectangular Column

Problem Statement

For the rectangular column designed in the previous example (400 mm × 600 mm with 8Ø20 longitudinal reinforcement), calculate the required transverse reinforcement (stirrups/ties) to resist the design shear force.

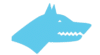

Given Data

| Parameter | Value |

|---|---|

| Column dimensions | b = 400 mm, h = 600 mm |

| Longitudinal reinforcement | 8Ø20 (from previous design) |

| Design shear force | Vd = 180 kN |

| Concrete class | C25 (fcd = 16.67 MPa, fctd = 1.04 MPa) |

| Steel class | S420 (fywd = 365 MPa) |

| Effective depth | d = 560 mm |

| Ductility level | Normal (Standard frame) |

THEORY – Shear Resistance in Columns

Maximum Shear Force Check

The column must satisfy the condition:

Note: If this condition is NOT satisfied, dimensions must be increased.

If satisfied: Calculate the required shear reinforcement considering the cracking contribution of concrete.

Shear Resistance Components

Where:

Vc = Concrete contribution to shear resistance

Vs = Stirrup/tie contribution to shear resistance

For Normal Ductility Level Columns:

Concrete Contribution:

Vcr = Vd – Vc (kN)

Stirrup Spacing:

Design Regions for Columns

CONFINEMENT ZONE (Near beam-column joints):

- Length = max(b/3, 8Ølong, 150 mm)

- Stricter spacing requirements

- s ≤ min(b/2, 12Ømin, 200 mm)

- Asw/sc ≥ 0.3 (fcd/fywd) b (minimum)

MIDDLE REGION:

- Less critical area

- s ≤ min(b/2, 12Ømin, 200 mm)

- Asw/so ≥ 0.3 (fcd/fywd) b

SOLUTION – Step by Step Design

Check Maximum Shear Force Capacity

Ac = b × h = 400 × 600 = 240,000 mm²

fcd = 16.67 MPa

0.22 Ac fcd = 0.22 × 240,000 × 16.67

= 879,648 N = 879.6 kN

Vd = 180 kN < 879.6 kN ✓

Calculate Required Stirrup Area for Shear

Concrete contribution to shear resistance:

For this example (no significant axial compression effect):

Vc = 0.8 × Vcr

Simplified calculation (conservative approach):

Vc ≈ 0.8 × 0.65 × 1.04 × 400 × 560

= 0.8 × 152,064 N = 121.7 kN

Required stirrup contribution:

Vs = 180 – 121.7 = 58.3 kN

The concrete alone can resist 121.7 kN of shear. We need stirrups to provide an additional 58.3 kN of shear resistance.

Calculate Required Stirrup Spacing

Let’s try Ø10 two-legged stirrups:

Two-legged stirrup: Asw = 2 × 78.5 = 157 mm²

Required spacing from shear:

s = (Asw × fywd × d) / Vs

s = (157 × 365 × 560) / (58,300)

s = 32,095,600 / 58,300

s = 550 mm

Apply Maximum Spacing Limits

Confinement Zone Requirements:

= max(400/3, 8×20, 150)

= max(133, 160, 150)

= 160 mm from column end

Maximum spacing in confinement zone:

sc ≤ min(b/2, 12Ømin, 200 mm)

= min(400/2, 12×10, 200)

= min(200, 120, 200)

= 120 mm

Middle Region Requirements:

so ≤ min(b/2, 12Ømin, 200 mm)

= 120 mm (same calculation)

Our calculated spacing from shear = 550 mm

Maximum allowed spacing = 120 mm

Therefore, spacing is controlled by maximum limits, not by shear requirements!

We will use s = 120 mm throughout.

Check Minimum Reinforcement Requirement

Asw/s ≥ 0.3 (fcd/fywd) b

Asw/s ≥ 0.3 × (16.67/365) × 400

Asw/s ≥ 0.3 × 0.0457 × 400

Asw/s ≥ 5.48 mm²/mm

For our design (Ø10, two-legged, s = 120 mm):

Asw/s = 157/120 = 1.31 mm²/mm

Our spacing of 120 mm does NOT satisfy minimum reinforcement!

Solution: Use larger diameter stirrups or reduce spacing.

Revise Design – Try Ø12 Stirrups

Two-legged stirrup: Asw = 2 × 113 = 226 mm²

Using s = 120 mm:

Asw/s = 226/120 = 1.88 mm²/mm

Still less than 5.48 ❌

Try reducing spacing to s = 80 mm:

Asw/s = 157/80 = 1.96 mm²/mm

Still less than 5.48 ❌

Try Ø12 stirrups with s = 40 mm:

5.65 > 5.48 ✓

Use Ø12 two-legged stirrups @ 40 mm spacing

Verify Shear Capacity with Final Design

Vs,provided = (Asw × fywd × d) / s

Vs,provided = (226 × 365 × 560) / 40

Vs,provided = 46,214,400 / 40

Vs,provided = 1,155,360 N = 1,155.4 kN

Total shear capacity:

VR = Vc + Vs,provided

VR = 121.7 + 1,155.4 = 1,277.1 kN

Vd = 180 kN < 1,277.1 kN ✓

Design Summary

Final Stirrup Arrangement

| Parameter | Value | Status |

|---|---|---|

| Design shear force (Vd) | 180 kN | Given |

| Maximum shear capacity | 879.6 kN | Adequate ✓ |

| Concrete contribution (Vc) | 121.7 kN | Calculated |

| Required stirrup contribution (Vs) | 58.3 kN | Calculated |

| Spacing from shear alone | 550 mm | Too large |

| Maximum allowed spacing | 120 mm | Code limit |

| Minimum Asw/s required | 5.48 mm²/mm | Code minimum |

| Confinement zone length | 160 mm from each end | Code requirement |

| Final stirrup design | Ø12 @ 40 mm | Satisfies all ✓ |

| Provided shear capacity | 1,277.1 kN | Very safe ✓ |

Key Design Insights

- Minimum reinforcement governs: Although shear requirements alone would allow 550mm spacing, code minimum reinforcement requires much tighter spacing (40mm).

- Over-designed for shear: The final design provides 1,277 kN capacity vs. 180 kN demand (710% safety factor).

- Practical considerations: Very tight stirrup spacing (40mm) may be difficult to construct. Consider using 4-legged stirrups or larger diameter with wider spacing.

- Alternative design: Could use Ø16 stirrups @ 80mm or Ø14 @ 60mm for better constructability.

- Confinement zones: Special attention needed at both ends (160mm from top and bottom) where beam-column joints occur.

Alternative Practical Design Options

Option 1: Four-legged stirrups

Asw = 4 × 78.5 = 314 mm²

Asw/s = 314/80 = 3.93 mm²/mm

Still < 5.48 ❌

Option 2: Larger diameter with reasonable spacing

Asw = 2 × 201 = 402 mm²

Asw/s = 402/80 = 5.03 mm²/mm

Still < 5.48 ❌ (close though!)

Option 3: Recommended practical solution

Asw = 2 × 154 = 308 mm²

Asw/s = 308/50 = 6.16 mm²/mm

6.16 > 5.48 ✓ (Better for construction!)

Construction Drawing Specification

COLUMN: 400 × 600 mm

Longitudinal Reinforcement: 8Ø20

Transverse Reinforcement (PRIMARY DESIGN): Ø12 @ 40 mm

Alternative (More Practical): Ø14 @ 50 mm

Confinement Zone: 160 mm from each end

Stirrup Configuration: Two-legged (rectangular ties)

Concrete: C25

Steel: S420

- This is a simplified design example. Actual design must consider all load combinations and detailing requirements.

- Very tight stirrup spacing may create concrete placement difficulties – coordinate with construction team.

- Local building codes (ACI 318, Eurocode 2, etc.) may have additional requirements.

- All designs must be reviewed and sealed by a licensed structural engineer.