Circular Reinforced Concrete Column Design

C30-S420 Material Column Longitudinal Reinforcement Calculation

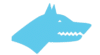

Problem Statement

For the circular cross-section column shown in the figure, made of C30-S420 materials, investigate the adequacy of the dimensions under the given loads and determine the required reinforcement using Ø16 diameter bars.

Given Material Properties

| Property | Value | Description |

|---|---|---|

| Concrete Class | C30 | Characteristic compressive strength: 30 MPa |

| Steel Class | S420 | Yield strength: 420 MPa |

| fcd | 20 MPa | Design concrete strength = 30/1.5 |

| fyd | 365 MPa | Design steel strength = 420/1.15 |

| fck | 30 MPa | Characteristic concrete strength |

Column Dimensions and Loading

Column Cross-Section

- Diameter (Ø): 350 mm

- Area (Ac): π × 175² = 96,211 mm²

- Reinforcement pattern: Bars equally spaced around perimeter

- Concrete cover: 30 mm (standard)

Loading Conditions

| Load Type | Axial Force (Nd) | Bending Moment (Md) |

|---|---|---|

| Design Load | 2500 kN (2500×10³ N) | 350 kNm (350×10⁶ Nmm) |

Note: These values represent factored design loads with safety factors applied.

SOLUTION – Step by Step Design Process

Verify Column Dimensions Based on Axial Load

Where:

Ac = π × (Ø/2)² = π × 175² = 96,211 mm²

fck = 30 MPa

Ndm = 0.5 × 96,211 × 30 = 1,443,165 N ≈ 1,443.2 kN

Nd = 2,500 kN > 1,443.2 kN ❌

This condition represents the threshold for the column to meet axial force code requirements.

Interpretation: The column is under high axial load, so reinforcement calculations will proceed accordingly.

The expression 0.5 × Ac × fck gives approximately half of the theoretical maximum axial load the concrete cross-section can carry. When this value is exceeded, the column is considered heavily loaded and requires increased reinforcement.

Calculate Dimensionless Ratios for Design Charts

2a. Normalized Axial Force (ν)

ν = 2,500 × 10³ / (96,211 × 20)

ν = 2,500,000 / 1,924,220

ν = 1.299 ≈ 1.30

ν = 1.30 indicates that 130% of the concrete’s compression capacity is being utilized. This high value signals that reinforcement will play a significant role.

2b. Eccentricity (e)

e = 350 × 10⁶ / (2,500 × 10³)

e = 140 mm

2c. Normalized Moment (μ)

μ = Md / (Ac × dn × fcd)

dn = Ø = 350 mm (diameter for circular sections)

μ = 350 × 10⁶ / (96,211 × 350 × 20)

μ = 350,000,000 / 673,477,000

μ = 0.52

μ = 0.52 indicates approximately 52% of the column’s moment capacity is being used. This represents a medium-high level of bending effect.

Determine Steel Coefficient (ψ) from Interaction Diagram

– ν = 1.30 (normalized axial force)

– μ = 0.52 (normalized moment)

From the chart with these values:

ψ ≈ 1.15

About Interaction Diagrams

Interaction diagrams are used to determine the required reinforcement ratio for the combined effect of axial load and moment in the column section. A high ν value (>1.0) indicates the column is under high compression and requires adequate reinforcement.ψ (psi) is a dimensionless coefficient representing the mechanical reinforcement ratio. This value is used to calculate the amount of reinforcement needed in the column section.

Calculate Required Steel Ratio

ρs = 1.15 × (20 / 365)

ρs = 1.15 × 0.0548

ρs = 0.0630 = 6.30%

Minimum steel ratio: ρmin = 1.0%

Calculated ratio: ρs = 6.30%

Maximum steel ratio: ρmax = 8.0%

6.30% > 1.0% and 6.30% < 8.0% ✓

Steel ratio is within code limits!

Due to the high axial load on the column (ν = 1.30), the concrete’s compression capacity alone is insufficient. The reinforcement bars play a crucial role in carrying this load.

Calculate Total Required Steel Area

Ast = 0.063 × 96,211

Ast = 6,061 mm²

The total cross-sectional area of all reinforcement bars to be placed around the column perimeter must be 6,061 mm². Now we need to determine how many bars and what diameter will provide this area.

Select Number and Diameter of Reinforcement Bars

Area of one Ø16 bar:

Abar = π × Ø²/4 = π × 16²/4 = 201 mm²

Required number of bars:

n = Ast / Abar = 6,061 / 201 = 30.15 ≈ 31 bars

Standard Bar Numbers

Common bar counts for circular columns: 6, 8, 10, 12, 14, 16, 18, 20, 22, 24…Since 31 is not a standard number, we select 32 bars (next even number).

Important: Always round up to ensure adequate steel area!

Verify Final Design

Area of one Ø16 bar = 201 mm²

Total area provided:

Ast,provided = 32 × 201 = 6,432 mm²

Required area:

Ast,required = 6,061 mm²

Check: 6,432 > 6,061 ✓

(32 bars of 16mm diameter)

- Provided steel area: 6,432 mm²

- Required steel area: 6,061 mm²

- Excess: 371 mm² (6.1% over – acceptable)

- Provided steel ratio: 6,432/96,211 = 6.68% ✓

- 1.0% < 6.68% < 8.0% (within code limits) ✓

Additional Checks and Design Rules

Bar Spacing Check

Perimeter length = π × Ø = π × 350 = 1,100 mm

Central angle between bars = 360° / 32 = 11.25°

Arc distance between bars ≈ 1,100 / 32 = 34.4 mm

Minimum spacing = 25 mm or bar diameter (16 mm)

34.4 mm > 25 mm ✓ (Adequate)

Transverse Reinforcement (Ties/Hoops) Design

- Minimum tie diameter: Ø8 mm (at least 1/4 of longitudinal bar diameter)

- Maximum spacing: 15 × longitudinal bar diameter = 15 × 16 = 240 mm

- or smallest column dimension = 350 mm

- Recommended: Ø10 ties @ 200 mm spacing

Design Summary

| Parameter | Value | Status |

|---|---|---|

| Column diameter | Ø350 mm | Given |

| Cross-sectional area (Ac) | 96,211 mm² | Calculated |

| Design axial force (Nd) | 2,500 kN | High load ✓ |

| Design moment (Md) | 350 kNm | Medium level ✓ |

| Normalized axial force (ν) | 1.30 | High ✓ |

| Normalized moment (μ) | 0.52 | Medium-high ✓ |

| Steel coefficient (ψ) | 1.15 | From chart ✓ |

| Required steel ratio (ρs) | 6.30% | High ✓ |

| Required steel area (Ast) | 6,061 mm² | Provided: 6,432 mm² ✓ |

| Final longitudinal reinforcement | 32Ø16 | Adequate ✓ |

Key Design Insights

- High Load Level: ν = 1.30 indicates the column is under high compressive load. Therefore, the reinforcement ratio is high (6.30%).

- Reinforcement Distribution: The 32 reinforcement bars must be placed at equal intervals of 11.25° around the column perimeter.

- Constructability: 32 bars is a practical number for a circular section, and the minimum spacing requirement between bars is satisfied.

- Safety Margin: The provided steel area is 6.1% more than required – this is a safe design.

- Code Compliance: The steel ratio (6.68%) is between minimum (1%) and maximum (8%) limits.

Construction Drawing Specification

COLUMN: Ø350 mm – Circular Section

Longitudinal Reinforcement: 32Ø16

(32 bars of Ø16 mm, equally spaced around perimeter)

Ties: Ø10 @ 200 mm

Concrete: C30

Steel: S420

Concrete Cover: 30 mm

These calculations are for educational purposes. In actual project applications, local building codes (ACI 318, Eurocode 2, etc.) must be considered and all designs should be reviewed by a licensed structural engineer.