Circular Reinforced Concrete Column

Axial Load Capacity & Spiral Reinforcement Design

Problem Statement

Design a circular reinforced concrete column with specified reinforcement. Given the moment capacity and steel configuration, determine:

a) Maximum axial load (Nd) the column can support based on interaction diagrams

b) Spiral tie spacing for Ø8 mm bars based on calculated axial load

Material Properties

| Property | Value | Description |

|---|---|---|

| Concrete Class | C25 | fck = 25 MPa |

| Steel Class | S420 | fyk = 420 MPa |

| fcd | 16.67 MPa | Design concrete strength (25/1.5) |

| fyd | 365 MPa | Design steel strength (420/1.15) |

| Cover | 25 mm | Concrete cover to reinforcement |

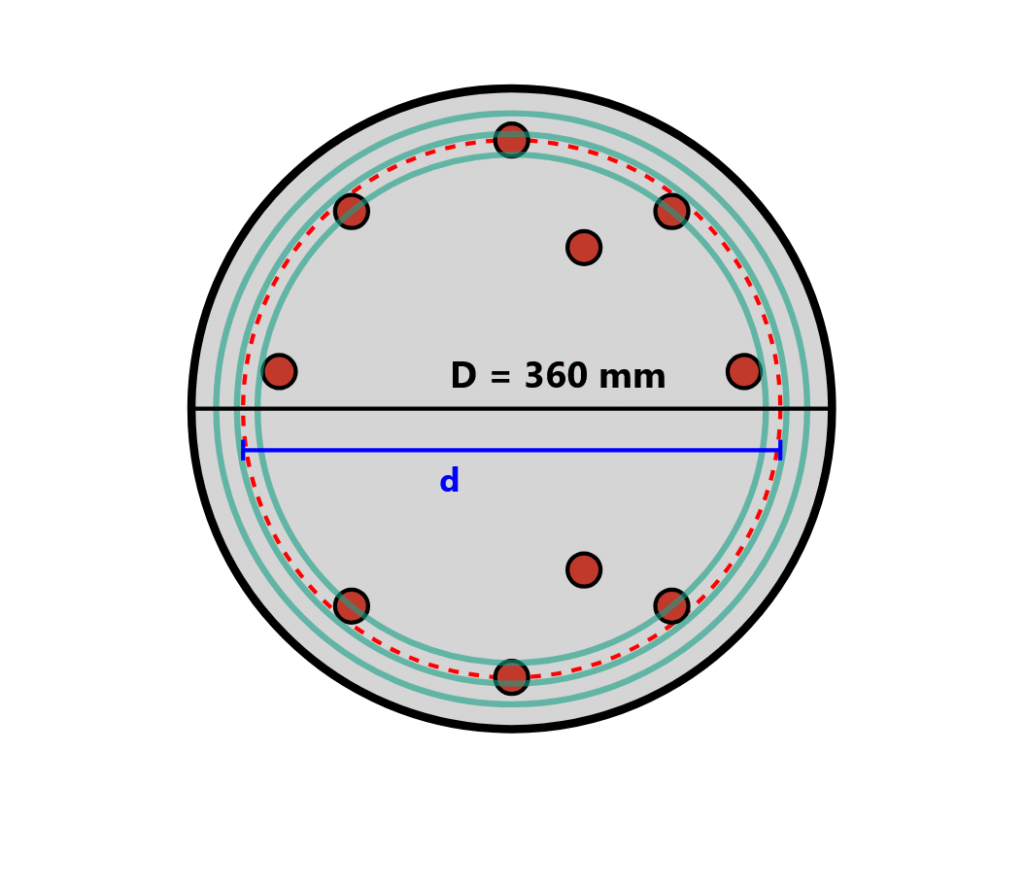

Column Geometry and Reinforcement

Circular Column Cross-Section

- Outer diameter (D): 360 mm

- Core diameter (dc): 310 mm (D – 2×cover)

- Concrete cover: 25 mm

- Longitudinal reinforcement: 10Ø16 bars uniformly distributed

- Transverse reinforcement: Ø8 spiral ties

Given Design Data

| Parameter | Value |

|---|---|

| Column diameter (D) | 360 mm |

| Core diameter (dc) | 310 mm |

| Longitudinal steel | 10Ø16 |

| Design moment (Md) | 108.96 kNm |

| Spiral bar size | Ø8 mm |

PART A: AXIAL LOAD CAPACITY DETERMINATION

Calculate Gross Concrete Area

Ac = π × 360² / 4

Ac = 3.14 × 129,600 / 4

Ac = 101,736 mm²

Calculate Core Area

Ack = π × 310² / 4

Ack = 3.14 × 96,100 / 4

Ack = 75,439 mm²

Calculate Total Longitudinal Steel Area

Ast = 10 × 201

Ast = 2,010 mm²

Calculate Steel Ratio

ρs = 2,010 / 101,736

ρs = 0.0198 ≈ 0.02 = 2.0%

Calculate Steel Coefficient (ψ)

ψ = 0.02 × (365 / 16.67)

ψ = 0.02 × 21.9

ψ = 0.438 ≈ 0.44

Calculate Normalized Moment

Where d ≈ 0.8D = 0.8 × 360 = 288 mm (effective depth for circular section)

μ = 108.96 × 10⁶ / (101,736 × 288 × 16.67)

μ = 108,960,000 / 488,545,536

μ = 0.223 ≈ 0.22

Determine Normalized Axial Force from Interaction Diagram

With ψ = 0.44 and μ = 0.22

Read: ν ≈ 0.55

Calculate Maximum Axial Load Capacity

Nd = ν × Ac × fcd

Nd = 0.55 × 101,736 × 16.67

Nd = 932,851 N

Nd ≈ 933 kN

Maximum axial load capacity: Nd = 933 kN

(For Md = 108.96 kNm)

PART B: SPIRAL TIE SPACING DESIGN

Check Axial Load Level

0.20 Ac fck = 0.20 × 101,736 × 25

= 508,680 N = 508.68 kN

Nd = 933 kN > 508.68 kN ✓

→ Spiral reinforcement design required

Calculate Minimum Volumetric Spiral Ratio

Option 1: 0.45 × [(Ac/Ack) – 1] × (fck/fywk)

ρsf ≥ 0.45 × [(101,736/75,439) – 1] × (25/420)

ρsf ≥ 0.45 × [1.348 – 1] × 0.0595

ρsf ≥ 0.45 × 0.348 × 0.0595

ρsf ≥ 0.0093

Option 2: 0.12 × (fck/fywk)

ρsf ≥ 0.12 × (25/420)

ρsf ≥ 0.12 × 0.0595

ρsf ≥ 0.00714

Governing: ρsf = 0.0093

Calculate Spiral Bar Area

Asp = π × 8² / 4

Asp = 3.14 × 64 / 4

Asp = 50.24 mm²

Calculate Required Spiral Spacing

Solving for s:

s = (4 × Asp) / (dc × ρsf)

s = (4 × 50.24) / (310 × 0.0093)

s = 200.96 / 2.883

s = 69.7 mm ≈ 70 mm

Check Maximum Spacing Limits

s ≤ D/5 = 360/5 = 72 mm

s ≤ 80 mm (general limit)

Calculated: s = 70 mm

Check: 70 mm < 72 mm ✓

Check: 70 mm < 80 mm ✓

Select Final Spiral Spacing

(Rounded down to nearest 5 mm for practical construction)

Spiral reinforcement: Ø8 @ 65 mm pitch

(8mm diameter bars at 65mm center-to-center spacing)

Complete Design Summary

| Design Parameter | Calculated Value | Final Design | Status |

|---|---|---|---|

| Column diameter | D = 360 mm | 360 mm | Given ✓ |

| Core diameter | dc = 310 mm | 310 mm | ✓ |

| Gross area | Ac = 101,736 mm² | – | ✓ |

| Core area | Ack = 75,439 mm² | – | ✓ |

| Longitudinal steel area | Ast = 2,010 mm² | 10Ø16 | Given ✓ |

| Steel ratio | ρs = 2.0% | Within limits | ✓ |

| Design moment | Md = 108.96 kNm | – | Given ✓ |

| Normalized moment | μ = 0.22 | – | ✓ |

| Steel coefficient | ψ = 0.44 | – | ✓ |

| Normalized axial force | ν = 0.55 | From diagram | ✓ |

| Axial capacity (Part a) | Nd = 933 kN | 933 kN | ✓ |

| Volumetric spiral ratio | ρsf = 0.0093 | Minimum required | ✓ |

| Spiral spacing calculated | s = 70 mm | – | ✓ |

| Spiral design (Part b) | s ≤ 72 mm | Ø8 @ 65 mm | ✓ |

Design Verification

Longitudinal Steel Verification:

- Steel ratio: 2.0% (within 1%-4% code limits) ✓

- Minimum bar diameter: Ø16 mm (adequate) ✓

- Number of bars: 10 (minimum 6 for circular columns) ✓

- Bar spacing: Uniform distribution around circumference ✓

Spiral Reinforcement Verification:

- Spiral diameter: Ø8 mm (minimum Ø6 mm) ✓

- Spacing: 65 mm (< 72 mm and < 80 mm limits) ✓

- Volumetric ratio: Meets both code equations ✓

- Confinement: Adequate for ductile behavior ✓

Capacity Checks:

- Axial load: 933 kN (with Md = 108.96 kNm) ✓

- Load level: > 20% Acfck (spiral required) ✓

- Interaction: Within column capacity envelope ✓

Key Design Insights

- Circular column advantages: Better confinement, improved ductility, uniform strength in all directions

- High steel ratio (2%): Provides significant moment capacity and enhanced axial load resistance

- Interaction design: The column can support 933 kN axial load when subjected to 108.96 kNm bending moment simultaneously

- Spiral confinement: 65mm spacing provides excellent core confinement, critical for seismic performance

- Practical construction: 10 bars allow for manageable spacing and ease of assembly

- Moment effect: Normalized moment μ = 0.22 indicates moderate bending, requiring consideration in interaction

- Spiral vs ties: Continuous spiral provides superior confinement compared to discrete rectangular ties

Final Construction Specification

CIRCULAR COLUMN: Ø360 mm

CORE DIAMETER: 310 mm

LONGITUDINAL REINFORCEMENT: 10Ø16

SPIRAL REINFORCEMENT: Ø8 @ 65 mm pitch

CONCRETE GRADE: C25 (fck = 25 MPa)

STEEL GRADE: S420 (fyk = 420 MPa)

CONCRETE COVER: 25 mm clear

DESIGN CAPACITY: Nd = 933 kN @ Md = 108.96 kNm