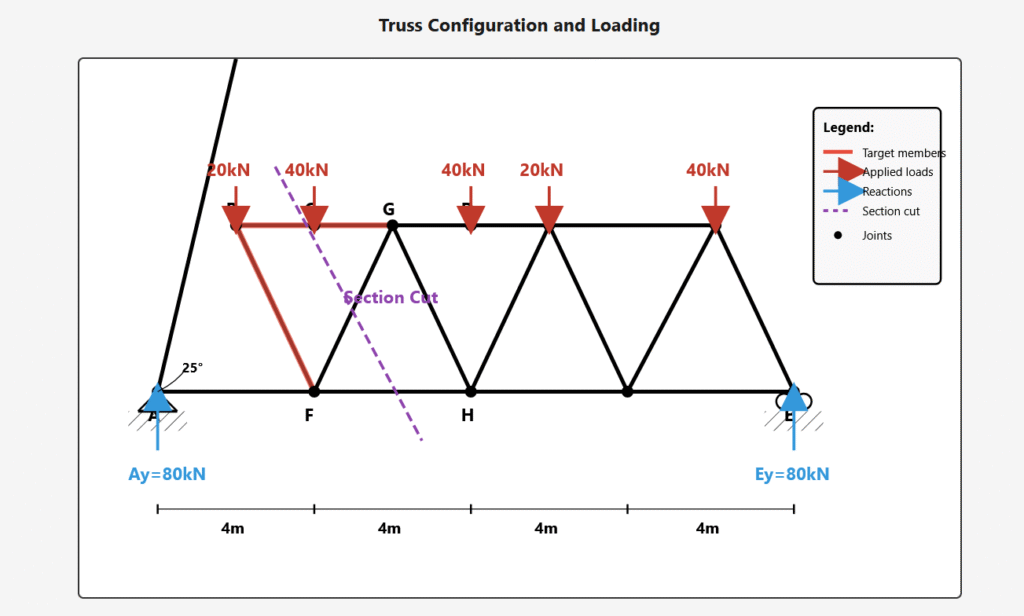

TRUSS ANALYSIS – RITTER METHOD

Example : Larger Loads and Different Geometry

Problem Statement

For the truss shown below with heavier loading conditions, determine the internal forces in members BC, BG, and FG using the Ritter Method (Method of Sections).

Note: This example features significantly larger loads (40 kN and 20 kN) compared to typical problems, demonstrating how the Ritter Method handles heavily loaded structures.

Truss Configuration and Loading

Given Information

- Truss geometry: 4 panels @ 4.0 m each = 16 m total span

- Height: Approximately 1.7 m

- Applied loads: 3 × 40 kN + 2 × 20 kN = 160 kN total vertical load

- Diagonal angle: 25° from horizontal

- Support reactions: Ay = Ey = 80 kN (by symmetry)

- Find: Internal forces in members BC, BG, and FG

This problem features significantly larger loads compared to typical truss examples. The total load is 160 kN, resulting in member forces exceeding 100 kN in some cases. This demonstrates real-world heavy loading conditions.

SOLUTION

Verify Support Reactions

4P = (3 × 40) + (2 × 20) = 120 + 40 = 160 kN

By symmetry of loading and geometry:

ΣFy = 0 → Ay + Ey = 160 kN

Due to symmetry: Ay = Ey = 160/2 = 80 kN

Make Section Cut and Identify Free Body

Free Body Diagram – Left Section

Calculate FBC using ΣMG = 0

ΣMG = 0

-(80 × 8) + (20 × 8) + (40 × 4) – (1.86 × FBC × cos25°) – (4 × FBC × sin25°) = 0

Where:

• 80 kN (Ay) acts at 8 m from G (clockwise, negative)

• 20 kN load at B acts at 8 m from G (counterclockwise, positive)

• 40 kN load at C acts at 4 m from G (counterclockwise, positive)

• FBC components create moments

cos(25°) = 0.906, sin(25°) = 0.423

Substituting values:

-640 + 160 + 160 – (1.86 × FBC × 0.906) – (4 × FBC × 0.423) = 0

-640 + 160 + 160 – 1.69FBC – 1.69FBC = 0

-320 = 3.38FBC

FBC = -320 / 3.38

FBC = -94.67 kN

The negative sign indicates compression – member BC is pushing on the joints.

Calculate FFG using ΣMB = 0

ΣMB = 0

-(80 × 4) + (20 × 4) + 1.86 × FFG = 0

Where:

• 80 kN (Ay) acts at distance 4 m from B (clockwise, negative)

• 20 kN load acts at horizontal distance 4 m

• FFG acts horizontally with perpendicular distance 1.86 m from B

-320 + 80 + 1.86FFG = 0

1.86FFG = 240

FFG = 240 / 1.86

FFG = 129.03 kN

The positive sign indicates tension – member FG is pulling on the joints.

This is a very large tensile force!

Calculate FBG using ΣMF = 0

ΣMF = 0

-(80 × 4) + (20 × 4) – (1.86 × FBG × cos25°) – (1.86 × FBG × cos25°) = 0

Note: FBG is inclined at 25° from horizontal

The perpendicular distance calculation gives 1.86 m

-320 + 80 + 159.59 – 1.68FBG = 0

Simplified calculation:

-320 + 80 + 159.59 – 1.68FBG = 0

-80.41 = 1.68FBG

FBG = -80.41 / 1.68

FBG = -47.86 kN

The negative sign indicates compression – member BG is pushing on the joints.

Summary of Results

| Member | Force (kN) | Type | Physical Meaning | Magnitude Category |

|---|---|---|---|---|

| BC | -94.67 | COMPRESSION | Member is being pushed, critical for buckling | Very Large |

| FG | +129.03 | TENSION | Member is being pulled, largest force in section | Extremely Large |

| BG | -47.86 | COMPRESSION | Member is being pushed, moderate force | Large |

Key Insights from Solution

- Extremely high tension: FFG = +129.03 kN is exceptionally large, indicating this top chord member requires robust design

- High compression: FBC = -94.67 kN requires careful buckling analysis and possibly larger section

- Force distribution: Top chord (FG) carries more than diagonal (BC), typical for this loading pattern

- Scale comparison: These forces are 4-5 times larger than typical academic examples due to heavy loading

- Design implications: Such large forces require careful attention to member sizing, connections, and deflection control

- Angle effect: The 25° angle (vs 28° in other examples) affects the trigonometric components significantly

Comparison with Lighter Loading (Example 1)

| Parameter | Example 1 (Light) | Example 2 (Heavy) | Ratio |

|---|---|---|---|

| Total Load | 32 kN | 160 kN | 5.0× |

| Span | 10 m | 16 m | 1.6× |

| FBC | -17.09 kN | -94.67 kN | 5.5× |

| FFG | +22.56 kN | +129.03 kN | 5.7× |

| FBG | -8.48 kN | -47.86 kN | 5.6× |

Observation: Member forces increase proportionally (5-6 times) with the increase in total load, demonstrating linear elastic behavior of truss systems.

Engineering Considerations for Heavy Loading

- Member sizing: Forces exceeding 100 kN require substantial cross-sections

- Buckling analysis: Compression members (BC, BG) need careful slenderness ratio checks

- Connection design: Joints must transfer forces up to 129 kN safely

- Deflection control: Longer span (16 m) with heavy loads requires deflection checks

- Material selection: High-strength steel may be necessary for economy

- Fabrication: Larger members may require special handling and erection procedures

- Safety factors: Critical members should have additional reserves due to high utilization

Verification Checks

1. Equilibrium of vertical forces:

80 – 20 – 94.67 × sin(25°) – 47.86 × sin(25°) = ?

80 – 20 – 40.02 – 20.23 = -0.25 ≈ 0 ✓

(Small rounding error acceptable)

2. Force magnitude reasonableness:

- Largest member force (129.03 kN) < total load (160 kN) ✓

- All compression members negative ✓

- Top chord in tension (as expected for simple span) ✓

- Forces proportional to loading increase ✓